Company History

By loading the video, you agree to Vimeos's privacy policy.

Learn more

Company History

SCHMIDT + HAENSCH has developed from a rich history of engineering and scientific research. The family-run company was founded in 1864 and has been part of innovative German technology from the beginning.

Today, our long-standing experience is the foundation of a company culture of reliability, excellence, and precision.

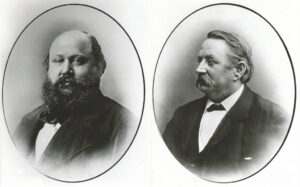

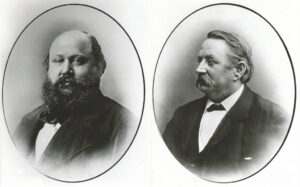

The company founders Franz Schmidt and Hermann Haensch

1864

We are in Berlin in the second half of the 19th century. The mechanic Franz Schmidt is working in a small workshop for physical instruments in the Alexandrinenstraße. The mechanic and optician Herrmann Haensch is managing a small business in the Adalbertstraße 82 and later in the Karlsstraße 8. They had trained to be mechanics with the same master craftsman, Wilhelm Langhoff. Using an inheritance of 8000 Thaler both decide in April 1864 to continue their activities together, laying the foundation for a company which today is proudly looking back to its more than 160 years heritage.

The company founders Franz Schmidt and Hermann Haensch

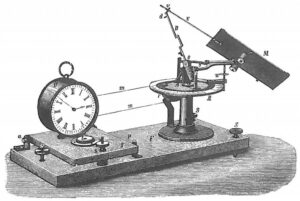

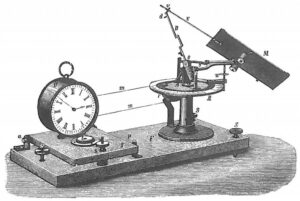

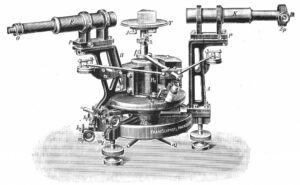

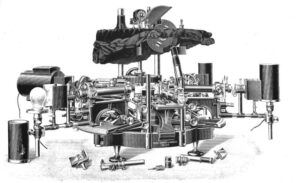

Heliostat according to Spencer

1870

For lack of electric light, the heliostat also was part of the standard equipment of optical instruments at SCHMIDT + HAENSCH. Here sunlight was caught with a mirror and the changing position of the incident sunlight was compensated by a gear coupled to a clock.

Heliostat according to Spencer

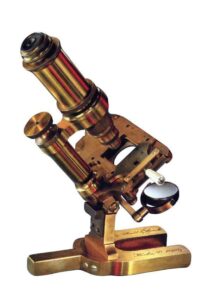

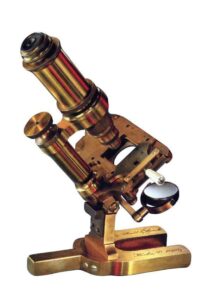

Trichinella microscope

1879

At the request of the famous pathologist Rudolph Virchow, SCHMIDT + HAENSCH constructs microscopes for the examination of meat, which should prevent the spreading of trichinosis. The pathologist wanted to prevent a long, drawn-out discussion about the most suitable microscopes. Even before publication of the document he had already contacted a mechanic in Berlin who had made a name for himself with the manufacturing of microscopes. “At my request, optician Hänsch [sic] in Berlin (Karlstraße 8) has constructed small microscopes for this specific purpose. They provide 100 to 180x magnification and cost only 10 to 12 Thalers.” (Rudolf Virchow)

Trichinella microscope

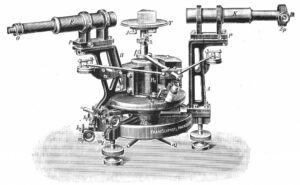

Spectrometer according to von Lang

1880

Electrically generated light was not yet used as it is today, not to mention the creation of a defined wavelength, interference, or edge filter. However, the gas-powered Bunsen burner already existed. Pure elements like sodium, potassium, and also mercury were burned in the Bunsen burner, and they emitted light with specific wavelengths. Thereby it was possible to produce the so-called standard wavelength with high precision. In the form of spectral light sources, those chemical elements they still play an important role today, because they very stably emit only one discrete wavelength.

Spectrometer according to von Lang

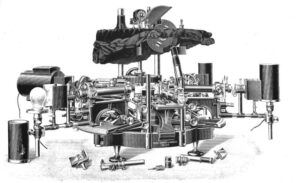

Michelson-Interferometer

1881

The foundation of Alexander Graham Bell assigned 2,000 USD to young Michelson who was in Berlin, eager to begin work on his experiment. Michelson used this money to commission SCHMIDT + HAENSCH to manufacture an instrument. Michelson knew how unique this experiment of testing the ether drift’s impact on the speed of light would be, and thanks to his acquisition of a measuring instrument from SCHMIDT+ HAENSCH, it was now actually within reach. The Michelson-Morley experiment in 1889 confirmed conclusively that the Earth’s motion against the ether, which had been assumed for a long time, did not actually exist. This discovery created a huge unexplained gap in experimental physics, which was only resolved by Albert Einstein’s special theory of relativity. For his groundbreaking research, Albert Abraham Michelson was awarded the Nobel Prize in Physics in 1907 and became the first American to receive the prize.

Michelson-Interferometer

Quartz wedge polarimeter (Polarimeter according to Karl Ventzke)

1890

A close relationship with the chemist Karl Ventzke of the Schicklersche Zuckerfabrik laid the foundation for effective sucrose measurement technology which is still being used today. This collaboration established the connection between the optical rotation of quartz and that of sucrose; this concept is still used to measure the sucrose content in sugar beet. Until today, the same optical principles are employed in the modern automatic quartz wedge polarimeter, the SCHMIDT + HAENSCH Saccharomat.

Quartz wedge polarimeter (Polarimeter according to Karl Ventzke)

Refractometer according to Pulfrich

1895

The basics of refractometry were developed by Ernst Abbe and Karl Pulfrich in 1869. A refractometer operating on the Pulfrich-principle and in accordance with Abbe was built by SCHMIDT + HAENSCH already in the 19th century.

Refractometer according to Pulfrich

Circle polarimeter used by the Swiss nobel price winner Alfred Werner

1905

Alfred Werner received the Nobel Prize in Chemistry in 1913. He was honored for his work on the arrangements of inorganic complexes. Contrary to prevailing opinion at the time, which was based on the chain theory by Danish chemist Sophus Mads Jørgensen, Werner developed a new structural model by using metal complexes like cobalt salts. He proposed the geometry of an octahedron and located two isomers at its vertices. His assumption, which was initially purely theoretical, was then successfully verified by means of a SCHMIDT + HAENSCH circular polarimeter in the labs of the ETH Zurich, the so-called catacombs. Even though it was a controversial issue in the beginning, this theory established a three-dimensional structural model as a basis for different spatial arrangements of organic and inorganic substances in relation to a central carbon molecule. To this day, this model has been crucial to the applications of polarimetry.

Circle polarimeter used by the Swiss nobel price winner Alfred Werner

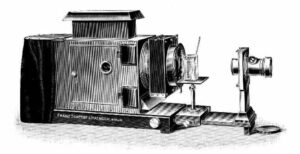

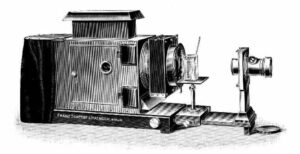

Projector

1910

In 1910 the company presented a projector which could be used by engineers and art historians alike: “The apparatus built in [the] Franz SCHMIDT + HAENSCH workshop not only allows the projection of transparent objects (diapositives, cuvettes, galvanoscopes, etc.), but can also project images of nontransparent lying or standing objects, such as illustrations from books, drawings, metal fractures, anatomical specimens on plates and in jars, bodily objects, and all chemical experiments carried out in vertical containers, as well as horizontal transparent objects, such as crystallizations, depictions of force lines, sound figures, etc.” (Wilhelm HAENSCH)

Projector

Color mixing apparatus according to Helmholtz-König

1921

With that device color standards were developed in the beginning of the 20th century, which were used for the calibration and control of signal lights. Prof. Manfred Richter, also known as “the holy father of colors”, needs to be mentioned here, with whom Mathis Kuchejda had the honor of working together in the national standardization of colors.Mr. Kuchejda will never forget the very calm and wise way, in which Richter pointed out, that the young members in the standards committee for color of the DIN would need a little bit longer to understand the complexity of color measurement and color mixing. “Young members” did not only refer to Mathis Kuchejda, who was in his mid 30s at that time, but also to various other colleagues, who bet on the spectral separation of light using interference filters. This should supersede the spectral mixing technique of the anomaloscope for the detection of the color deficiency of the human color perception, which was produced by SCHMIDT + HAENSCH as well.

Color mixing apparatus according to Helmholtz-König

ISIS drafting machine

1955

At the very first trade show after the war, Herbert Kuchejda, who was partner in the company at that time, exhibited a drafting table. Drafting tables were not even part of the range of products. SCHMIDT + HAENSCH had a drafting table, and Victor Graf from Gotha had the drafting machine. They quickly reached an agreement. Graf sold the rights to the drawing instruments to SCHMIDT + HAENSCH. By the way, he was an amateur Egyptologist and had therefore called his drawing instruments ISIS. The risk of this purchase paid off. In his letters, Herbert Kuchejda proudly writes about selling 250 tables –a huge quantity for the beginning—to a customer. Production grew rapidly. Later, SCHMIDT + HAENSCH even had to work shifts. The drafting machines went like hotcakes. They were not sold but rather distributed to the customers.

ISIS drafting machine

Heyday of the drafting machines

1960 – 1990

Between the years 1960 and 1990 the production of drafting machines and tables became the company’s mainstay of sales.

Heyday of the drafting machines

Saccharomat II

1963

The worldwide first, fully automatic sugar polarimeter with digital display and printer was developed and built by SCHMIDT + HAENSCH.

Saccharomat II

Opening of the factory Köln-Lövenich

1969

Due to lack to space as well as the political situation of West Berlin (still considered to be insecure by many of the major customers who remembered Berlin Blockade), the former management decided to move part of the production and logistics from Berlin to Cologne. High industrial density in North Rhine-Westphalia allowed for direct delivery to clients in that region.

Opening of the factory Köln-Lövenich

Digitising table

1982

The first version of the worldwide successful digitizing table of SCHMIDT + HAENSCH was published. This table was very popular in the 1980s and 90s and put the company into a leading position in the world market in this sector.

Digitising table

Mathis Kuchejda was named managing director

1983

The former managing director Walter Teller, who succeeded Herbert Kuchejda after he passed away, retired at the end of 1982 after working 50 years in the company. Mathis Kuchejda was strongly recommended to take over the management, even if his professional orientation had been completely different till then. Today, the company is managed by the fifth generation of the families SCHMIDT and HAENSCH.

Mathis Kuchejda was named managing director

DUR W

1986

First fully-automatic table refractometer with measuring range up to 1.72000 and a resolution of 10⁻⁵ Brix.

DUR W

Celebration 125th anniversary of SCHMIDT + HAENSCH

1989

Gala dinner in the Hotel Berlin am Lützowplatz on 24th of April 1989.

Celebration 125th anniversary of SCHMIDT + HAENSCH

First titration system

2000

The SCHMIDT + HAENSCH titration system is developed to realize automated on-line titrations under difficult process and environmental conditions. The system allows fast measuring cycles with high reliability. The first delivery was made in August 2000.

First titration system

Ash Color Turbidity Analyser

2003

Development and production of the first automatic ash-color-turbity measuring device which reduces the complete analysis time from 1 hour to 10 minutes.

Ash Color Turbidity Analyser

Online Purity Analyser

2005

Development and production of the first on-line purity system.

Online Purity Analyser

Celebration 150th anniversary of SCHMIDT + HAENSCH

2014

SCHMIDT + HAENSCH celebrates the 150th anniversary with a reception in the Audimax at the EUREF-Campus and a soiree at Capitol Yard Golf Lounge.

Celebration 150th anniversary of SCHMIDT + HAENSCH

VariDens - Density meter

2015 until today

Based on the high level of fine mechanics and optics, today SCHMIDT + HAENSCH produces and distributes high-quality refractometers and polarimeters, density meters, and color measuring devices all over the world. The realm of laboratory measuring instruments is completed by the areas of process technology and automation to satisfy the demand for on-line information processing and control. The modular construction of the opto-electronic measuring systems allows a high flexibility and customer specific solutions. SCHMIDT + HAENSCH employs a highly qualified team of developers and manufacturing specialists to guarantee a constant high product quality and sustain and strengthen its leading position in the market all over the world. The company not only produces standard instruments, but it also adapts the measuring devices to special requirements of the customer. In addition, SCHMIDT + HAENSCH is constantly developing new applications and procedures in cooperation with the customers. Today, the company collaborates with universities, colleges, and other research institutes to develop new instruments, optimize methods, and support scientific discoveries.

VariDens - Density meter