Halfway to XR5.0: Redefining Remote Maintenance with SCHMIDT + HAENSCH

As the XR5.0 project reaches its midpoint, SCHMIDT + HAENSCH continues to pioneer the future of smart maintenance in laboratory and process instrumentation. Together with more than 25 European partners, we are translating the ambitious vision of Industry 5.0 into real-world tools—tools that combine extended reality (XR), artificial intelligence (AI), and human-centric design to transform how industrial maintenance is performed.

From Vision to Validation: Where We Stand

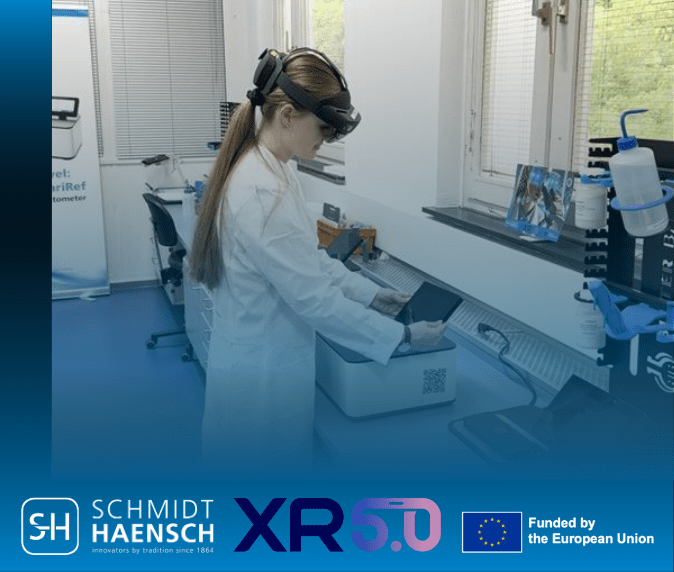

Since the project’s launch, SCHMIDT + HAENSCH has successfully integrated XR5.0 prototypes into real maintenance scenarios. With a global installed base of high-precision instruments—polarimeters, refractometers, and inline sensors—we’ve had ample opportunity to test XR-enhanced support in the field.

Key milestones achieved so far include:

- Successful Pilot Deployments: XR-enabled service procedures have been piloted with both internal service engineers and external partners. These pilots demonstrate significant reductions in troubleshooting time and improved first-time fix rates.

- AI-Based Skill Adaptation: Our system now recognizes technician experience levels and adapts instructions accordingly. Whether the user is an in-house expert or a new operator, the interface delivers step-by-step support that is context-aware and intuitive.

- Reduced Downtime, Reduced Travel: Remote troubleshooting, calibration, and validation have proven effective, minimizing the need for travel while keeping instruments operational even in remote or regulated environments.

Use Case Highlight: Supporting Global Partners

A major focus has been enabling distributors and field technicians across the globe to carry out diagnostics, retrofitting, and even complex maintenance—with guidance from SCHMIDT + HAENSCH experts in Berlin. Using smart glasses and AR overlays, technicians receive real-time instructions, diagrams, and verbal assistance in their local context—without needing to fly in a specialist.

This not only improves efficiency but also aligns with our sustainability goals, reducing the carbon footprint of service operations and making high-quality support accessible across time zones.

For instance, SCHMIDT + HAENSCH’s Service Technician Experts can remotely oversee and assist Field Technicians or Equipment Operators via AI-enhanced visualizations, delivering step-by-step instructions that adapt to each user’s skill level. This personalized assistance not only improves task accuracy and safety but also enables swift, informed decision-making in the field. Equipment operators can now independently handle basic maintenance tasks while having a reliable support network for more complex issues.

Challenges and Learnings

As with any transformative technology, implementation brings challenges:

- Connectivity Constraints: Reliable XR support depends on stable internet connections—especially in remote industrial environments.

- User Adoption: Training and onboarding remain critical to help users embrace new tools. We’ve found that once initial barriers are overcome, user satisfaction and confidence increase rapidly.

These lessons are shaping our ongoing development and are shared across the XR5.0 consortium to refine the overall platform.

Looking Ahead: Scalable, Smart Service for Industry 5.0

In the coming months, SCHMIDT + HAENSCH will continue:

- Expanding real-world deployments of the XR tools across additional service scenarios

- Collecting performance data to quantify improvements in service efficiency and sustainability

- Working with consortium partners to finalize a market-ready XR5.0 maintenance platform

Our goal remains clear: to provide a flexible, scalable, and intelligent maintenance solution that supports the transition toward more resilient, human-centered, and resource-efficient industries.

Want to See XR5.0 in Action?

We’re actively scheduling demonstrations and pilot partnerships. If you’re interested in how XR-enhanced maintenance could benefit your operations, reach out to our team or visit xr50.eu to learn more.