Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

Schmidt + Haensch has developed this modular, computer-aided automated laboratory system, based on optoelectronic measuring instruments, which includes not only polarimeters and refractometers but also sugar colorimeters and conductometric ash determination. The system may also be upgraded with pH-determining electrodes, balances, barcode scanners, and all necessary instruments for measuring the most important values in the sugar industry. Schmidt + Haensch is proud to offer systems tailored with different degrees of automation to meet each customer’s needs.

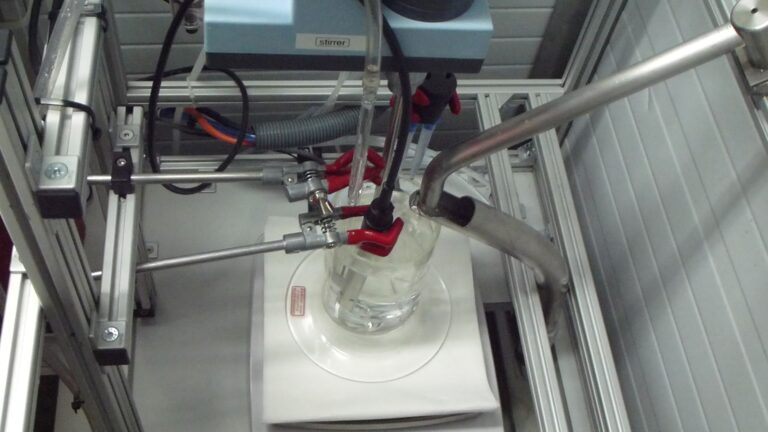

The Schmidt + Haensch Purity Analyzer is a standalone PC-controlled system containing a colorimeter, a scale, and a conductometer with all necessary pumps and valves for fluid handling, requiring only a few preparations before automatically analyzing the sugar product:

All of the above will take only one minute to finish; after 25 to 30 minutes (depending on the sample) a full analysis will be completed and a new run can be started immediately.

As a purity criterion for sugar and other products of the sugar industry, the conductometric determination of ash is the preferred feature as it is closely related to sulphated ash. Conductivity can be rapidly measured with reproducible results, and it is contained in most domestic and international sugar quality regulations.

The Automatic Ash-Color-Turbidity Analyzer of Schmidt + Haensch measures the conductivity in accordance with the official ICUMSA method in a 28 Bx solution (ICUMSA 2002, GS2/3-17). The measuring data can be collected by a data acquisition software package, processed, stored in a data base, and exported to a LIMS system.

The system is easy to use, delivers reliable results, and saves valuable time that the laboratory personnel can use for other, non-routine work. It is specially designed for sugar laboratories with high sample throughput. An example is the combined automatic determination of conductometric ash and color (ICUMSA) for the sugar industry. The crystalline sugar sample is manually added – no further preparation is necessary – and the sample ID can be detected with a barcode scanner. The system dissolves the sample automatically and dilutes the solution to a defined concentration (50 Brix). It automatically filters the sample and fills the specially designed flow-through tube of the Coloromat. The measurement is carried out at 420 nm according to ICUMSA (2002, GS2/3-17). In a second step, the system further dilutes the solution to 28 Brix to measure the conductometric ash. All measurements are operated continuously. Finally, the whole system is rinsed with water and is ready for the measurement of the next sample; the complete measuring sequence takes ten minutes compared to an hour if handled manually. The measuring values are transmitted to a PC that also controls the whole system, calculates the required results, and transmits all data to a LIMS or MIS system.

| Precision colour | ± 1 IU ( up to 30 IU) |

| Precision colour of turbidity | ± 10 % |

| Precision ash | ± 0.001 % |

| Brix liquidity | ± 0.1 Brix |

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.