Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

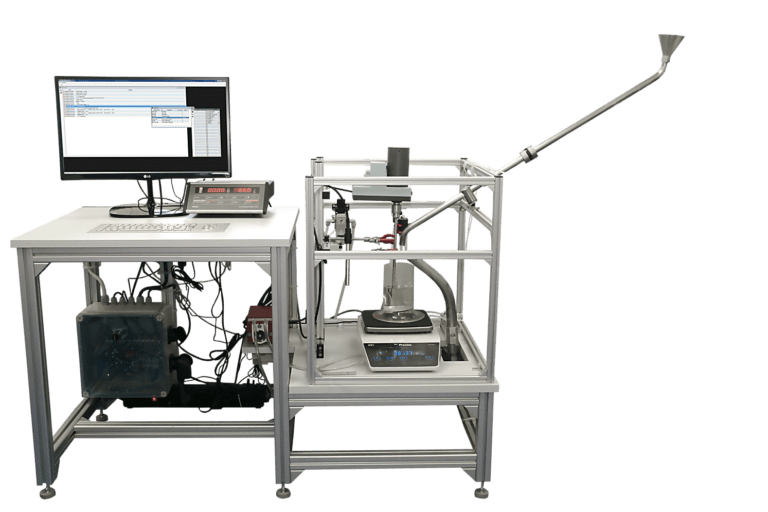

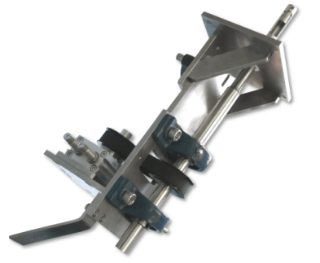

SCHMIDT + HAENSCH offers an on-line ash analyzer in order to monitor the quality of dried white sugar crystals. The device consists of an automatic sampling system which can also be used in hazardous Atex-zones using conductivity to determine the non-sugar content. The device fulfills the standard lab procedure for ash determination following ICUMSA regulations.

ID-N° 14850

The SCHMIDT + HAENSCH on-line ash analyzer is a stand-alone, PC-controlled analyzer requiring just a few preparation steps before sample analysis. The preparation time is about 1 minute and the measurement time of the sample is 25 to 30 minutes. The device is normally implemented after the drying drum and takes random samples before they reach the conveyor belts.

The goal is to separate the ABC-sugars and direct them to the according storage premises.

The conductometric determination of ash is a standards ICUMSA method to determine the purity of crystal sugar. The device immediately allocates different sugar qualities to respective silos. The unwanted mixing of different sugar qualities is therefore avoided. Inorganic components in sugar – remaining after complete incineration of organic substances – are defined as ash. As a purity criterion for sugar and related products the conductometric determination of ash is preferred as it is closely related to sulphated ash.

In preparation of your coming campaign please contact us for further information.

The system dissolves the sample automatically and dilutes the solution to a defined concentration (28 Brix). Measurement results are immediately transferred to the control room of the sugar factory, enabling personnel to react to changes in sugar production.

Finally, the whole system is recalibrated with distilled water and ready for the measurement of the next sample. The complete measuring sequence takes 5 minutes compared to a much longer handling time.

The measurement data are transmitted to a PC that also controls the whole system, calculates the required results, and transmits all data to a PLC or MIS system.

Conductivity calculated [μS/cm] CC

CC = (CM 0.35 * CW)/(1+0.026 * (T-20))

Conductivity ash

Conductivity ash = 0.0006 * CC * T24 (T24 is normally 1.0

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.