Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

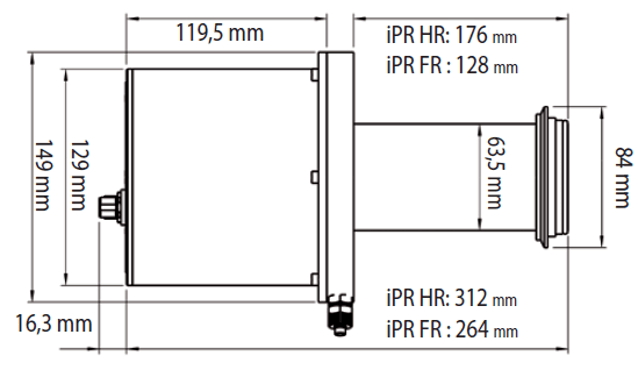

A flagship in our product folio is the inline Process Refractometer-Full Range2. It is outwardly indistinguishable from the iPR HR2 but the integrated optics and electronics are designed to provide a particularly very wide measuring range from 1.3200 – 1.5300 RI (0-100 Brix). Without major compromises in resolution of 0.01 Brix and accuracy from +/- 0.05 Brix. Thanks to its integrated water cooling system, measurements at process temperatures of up to 150 °C are easily possible.

ID-N° 10970 VariVent connection

ID-N° 10971 TriClamp connection

ID-N° 10972 APV connection

The refractometer iPR FR2 is a stand-alone process sensor with integrated, illuminated display which does not require an external electronic unit. Its special design and electronic configuration make it highly flexible and easy to operate. The programming with Microsoft Windows software is also straightforward. Optional Data Logger is also available. The iPR FR2 measuring head can be installed in pipes, reactor vessels, mixing tanks, kettles, boiling pans, and evaporators, using different weld-in flanges.

The iPR FR2 delivers lab quality industrial measurements for a range of industries, including food and beverage, chemical, pharmaceutical, medical, and packaging industries.

Applications include condensate measurement, control of disinfectants for packaging, purity control for pharmaceuticals, liquid-liquid extraction and many more.

This process refractometer lasts in the roughest conditions while delivering precise and reliable industrial measurements. With a certified IP69K protection class tested by the reliable German standardization institution TÜV, it can simultaneously withstand aggressive chemicals and high temperatures.

For flexibility in use, the product has two analog and two digital interfaces so that you can fully and easily integrate the measuring head into your production process.

A selection of cost-effective process flanges, the VariVent, and other connection devices accompany the iPR-H3, with which the instrument is technically easy to implement.

With the pig pipe addition, the iPR FR2 allows for Cleaning In Place (CIP).

| Measuring range 1 | 1.3200 – 1.5300 RI / 0-100 Brix |

| Measuring range 2 | 1.4200 – 1.6000 RI / 50 – 100 Brix |

| Resolution | 0.00001 RI / 0.01 Brix |

| Accuracy | ± 0.00007 RI / ± 0.05 Brix at 25° C |

| Process temperature | -10 °C to 150 °C (with water cooling) |

| Ambient temperature | -10 ° to +45 °C |

| Pressure load capacity | MPa (145 psi, 10 bar) – up to 30 bar available with APV conncection |

| Temperature measurement | NTC sensor for measurement of sample temperature placed inside the prism |

| Interfaces | 2 insulated 4 – 20 mA analog outputs 2 digital output switch (up to 1 A) 1 serial output (RS232, alternativly RS485 or USB) |

| Power supply | 24 V DC |

| Prism | Sapphire |

| Light source / wavelength | 589 nm LED |

| Process pressure (max.) | MPa (145 psi, 10 bar) |

| Process contact material | Sapphire, Stainless steel or Hastelloy |

| Mounting accessories | VariVent (Tuchenhagen), APV or TriClamp* |

* Optional

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.