Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

A fast and accurate analysis of the liming process is an important step in juice purification in a sugar factory. The on-line process analysis enables continuous process monitoring of the beet juice, enabling immediate process regulation. The automated sampling process optimizes reliability.

ID-N° 11548

The complete system is controlled by a computing system which also controls all actuators and sensors using specially designed software for the application. All actions of the analysis process can be monitored online. After concluding the titration and calculation of results, all data can be transferred to external MIS or data base systems via standard interfaces.

A component of the pre and/or main liming tank is guided to a sample selection system which takes the sample to the measuring module. The order of the sample selection can be configured to your current needs. In the process titration module, the sample volume is prepared in a defined way. Hot samples are cooled down in the double-jacketed reactor, followed by the titration which uses a pH electrode to control the titration volume.

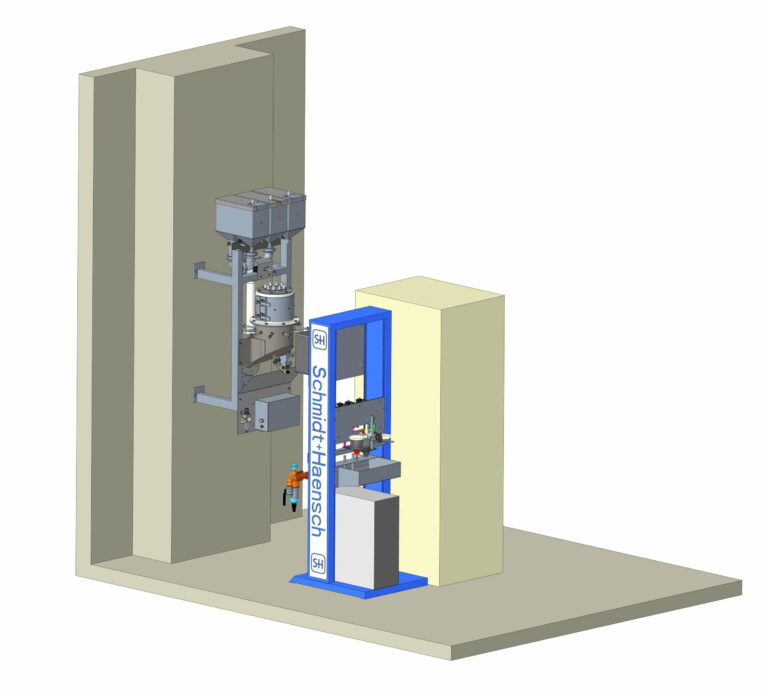

The modular system can integrate several Schmidt + Haensch instruments. The modular concept and individual software modules allow us to offer flexible, customer tailored solutions. The system can analyze samples ranging from raw materials, intermediate products, up to the quality control of the final product.

The automatic value determination results in a higher analysis frequency and offers current information about the process control. It can rapidly detect variations of the pH-value. The on-line titration system allows the exact dosing of lime to improve clarification and to reduce overdosing. Determination of alkalinity can reduce the consumption of limestone and coke. The aim is to optimize process performance, avoid product losses, and control limit levels. To this end, Schmidt + Haensch instruments are designed to monitor characteristics of process streams.

System Construction

Operation

Processing of Results

Maintenance/Service

Applications

Titrations, resp. including ph measurements in the sugar industry, chemical industry, etc.

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.