Monitor air conditioning systems

Propylene glycol is a versatile industrial compound that is particularly well suited for applications requiring reliable protection against freezing due to its freezing point depression properties. Propylene glycol is used in numerous areas such as antifreeze agents, heat transfer fluids in cooling and heating systems, as a carrier substance in the food and pharmaceutical industries, in cosmetics, as a humectant, and in hydraulic fluids. It is also used as a flavor carrier in e-liquids for e-cigarettes in the tobacco industry and in aviation for de-icing aircraft wings.

Chemically, propylene glycol (1,2-propanediol, IUPAC: propane-1,2-diol) is a colorless, almost odorless, viscous liquid with a slightly sweet taste. Unlike ethylene glycol, propylene glycol is less toxic and is therefore approved for many applications involving direct or indirect contact with humans. Industrial production mainly involves the hydration of propylene oxide. This produces both the isomeric 1,2-propanediol (propylene glycol) and small amounts of 1,3-propanediol. The raw material propylene oxide is reacted with water under acidic or basic conditions.

For use in cooling circuits, propylene glycol is mixed with water in specific concentrations to achieve the desired freezing and boiling points. Monitoring these concentrations is crucial, especially in large air conditioning systems, industrial cooling systems, and heat pumps, to ensure optimal efficiency and process reliability.

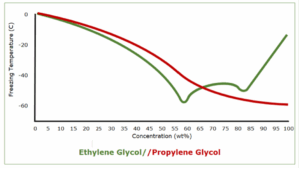

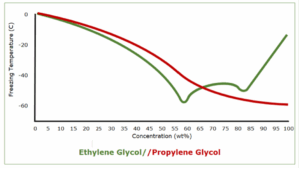

To determine the concentration of propylene glycol, the weight percentage %wt is measured using its refractive index with our laboratory and process refractometers. The VariRef is available for laboratory use, while the iCS2 and iPR C2 models are ideal for applications in ongoing processes. By using the particularly small iCS2 concentration sensor, maintenance intervals can be efficiently optimized and frost damage reliably avoided. Such damage often occurs when the mixing ratio of the heat transfer fluid is not set correctly: when freezing, the fluid expands – especially since propylene glycol and ethylene glycol have different freezing points. This expansion can cause considerable damage to pipes and containers.

Source: https://bluefieldsafety.com/2023/10/aint-misbehavin-frozen-pipes-when-its-warm/

The iPR C2 process refractometer can also be used for precise real-time monitoring of propylene glycol concentration in cooling and heating systems, such as in data centers, food processing plants, or building services engineering. All devices measure at a wavelength of 589 nm and can be used in a wide temperature range down to -30°C.

No sample preparation is required, enabling seamless integration into your workflow – both for precise offline analysis in the laboratory and for real-time monitoring inline or online directly in the process. This ensures maximum efficiency in quality control and minimal disruption to your operations. Trust in the proven measurement technology from SCHMIDT + HAENSCH – for reliable control of your propylene glycol coolants.