Educational

What is in-line process refractometry?

Process Analytical Technology (PAT) and industrial measurements

Refractometry is generally speaking the measurement of refractive index and its interpretation under different starting points. Refractometric measurements can be performed in laboratories or in-line, meaning during a production process of liquid subsances of any kind. This in-line technology is referred to as “Process Analytical Technology” or “PAT”.

Refractometric in-line PAT can be used for purity investigations, sample recognition, dilution control or composition. It’s also used for characterization of substances or for determination of substance data, especially of organic liquids. The examination and quality control of oils, fats, sugar and sugar containing substances are the traditional main areas of refractive in-line measurement. Additionally lemonade, beer and alcoholic beverages belong to the material class which are typically analyzed by a sensor. Generally speaking, the vast majority of liquid substances are measureable with SCHMIDT + HAENSCH PAT. To find about our measuring scales for refractometers, click here.

Measuring physical parameters of liquid substances in-line with the production process

Process Analytical Technology (PAT) is a manufacturing methodology for high value chemicals, pharmaceuticals and foods and beverages. Critical parameters (CPPs) and key performance indicators (KPIs) of the process are thoroughly understood, well-defined and continually monitored in order to ensure that the pre-defined critical quality attributes (CQA) of the final product are consistently achieved. SCHMIDT + HAENSCH PAT measures key quality and performance indicators in raw materials, in-process materials and processes in real-time. A well designed PAT-based process is stable, ensuring that the critical parameters and indicators remain within pre-described limits to ensure product quality and process safety. PAT is an important element in quality control system, in which quality is not tested into product, but rather inherent, by-design. PAT is an orthogonalized application of chemical, physical, microbiological, mathematical and risk analysis elements resulting in a complete understanding and control of processes. PAT is applicable to many standard operations performed in chemical processes, including reaction monitoring and crystallization procedures. Hence, SCHMIDT + HAENSCH process refractometers and sensors are developed for different requirements. Our process Refractometers are used for in-line liquid measurements for the purpose of process control and industrial automation. We invest heavily in research and development, maintaining a worldwide reputation for innovation, reliability and high quality.

The performance of all types of refining, manufacturing and quality control operations can be dramatically improved with our digital refractometer technology.For instance, the in-line concentration measurement can be used as a real-time predictive tool for the final concentration. A quick and accurate response is needed to optimize production. Cost reduction is possible by reducing the variation of mean average of the product concentration. The cost saving is related to the value of the component being measured.

The range of refractometer applications is wide as most liquid processes require continuous monitoring of concentration to help maintain quality and reduce costs. SCHMIDT + HAENSCH serves the target industries according to their different nature and technology requirements to ensure a high standard of products and services. Click here to learn about the refractometer models and applications.

Installation of process refractometers and sensors

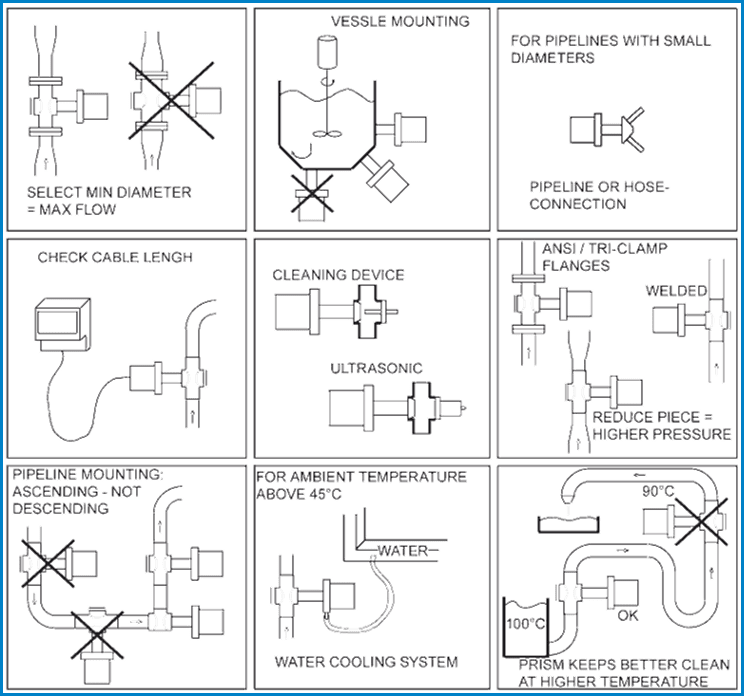

The installation graphic demonstrates the installation options and the positioning of the process refractometers in the production process. The position and the environment around the instrument may be a decisive factor for the refractometric measurement. Some production processes deal with harsh conditions, high temperatures or aggressive chemicals.

SCHMIDT + HAENSCH’s variety of process sensors and refractometers answer to these requirements and consider the correct mounting accessories for each production process.

Do you have any questions?

We will be happy to help you