Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Educational

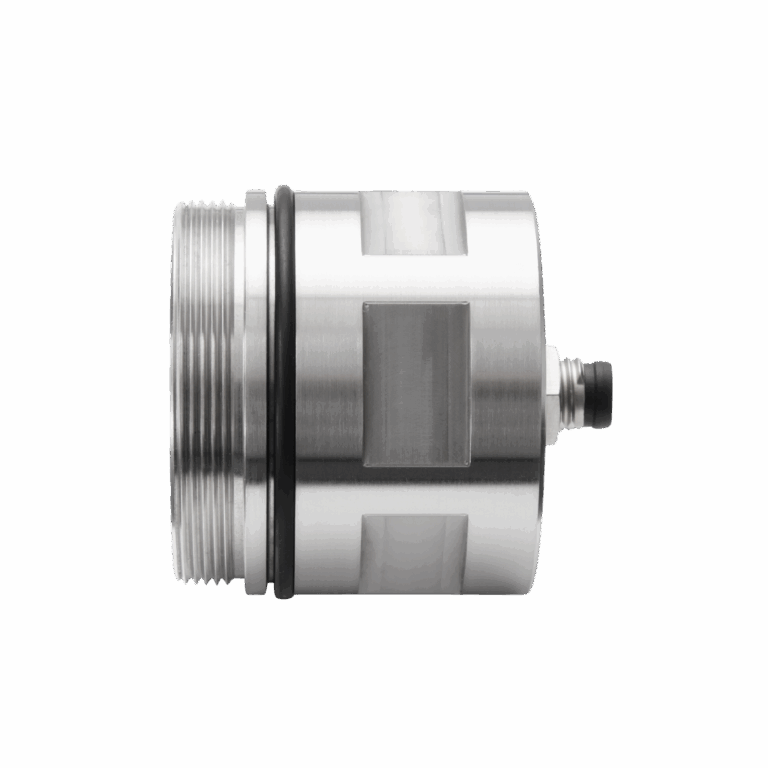

The iCS² inline process sensor stands for reliable and continuous concentration measurement in the smallest of spaces – ideal for use in ongoing processes with cooling lubricants, antifreeze and many other substances. Thanks to its compact design, the sensor can be installed quickly and easily. Once installed, it works reliably and continuously – without interruptions and without the need for cleaning. If required, the sensor can be quickly and flexibly adapted to a wide range of inline process requirements and products. Thanks to its robust insensitivity to ambient light and dirt and virtually maintenance-free functionality, the sensor continuously delivers precise measurement results even under extreme conditions. Small in size, big in effect: the iCS² masters every challenge in the process and delivers stable results even where other sensors reach their limits.

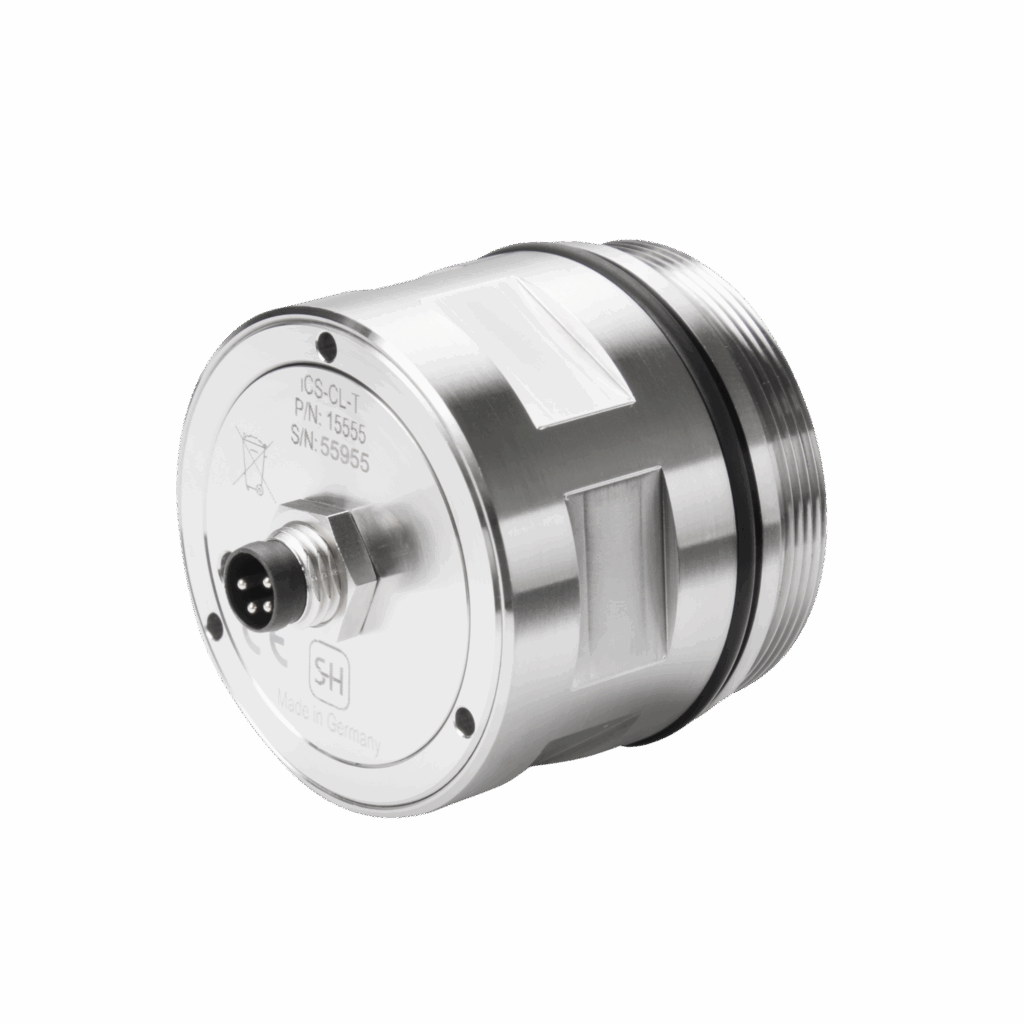

SCHMIDT + HAENSCH has the ultimate solution for you if you are dealing with heavily contaminated liquids, space-limited installations or exposure to ambient light: designed for easy integration into your process control system, it can be connected directly to your PLC via an RS485 Modbus RTU interface. Integrated functions such as temperature measurement and level detection ensure a self-monitoring system. Our user-friendly software for data acquisition and configuration of the device is also included in the scope of delivery.

The iCS2 inline process sensor was specially developed for reliable, maintenance-free quality control of contaminated and turbid liquids in space-critical environments. With its particularly large measuring surface and robust design, it is ideal for media such as cooling lubricants and antifreeze. The sensor covers a wide range of applications and can be individually programmed to the desired measuring range.

Do you have a special requirement? Our experienced team of engineers will adapt the sensor exactly to your application – contact us!

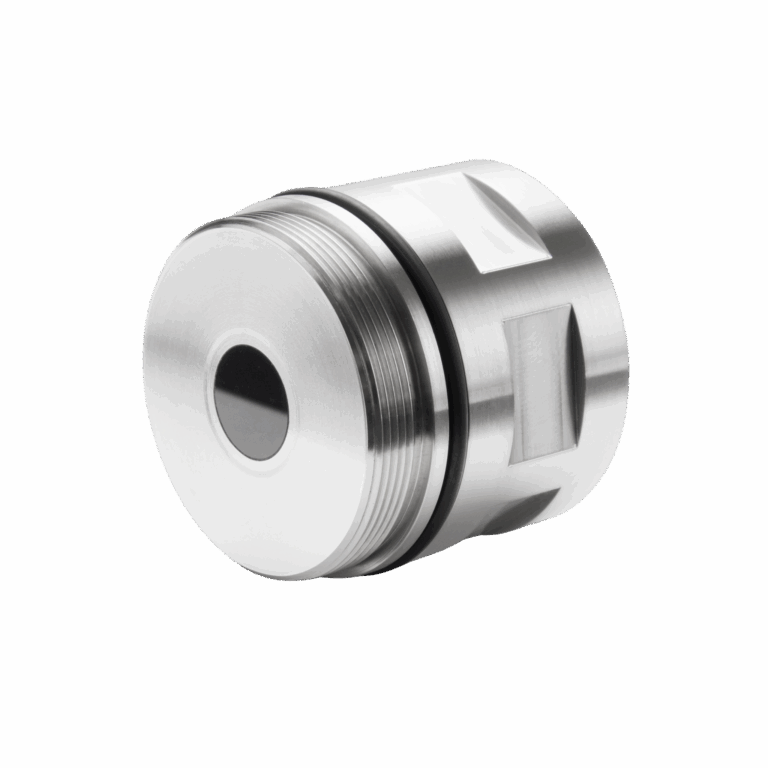

Equipped with a light source at 589 nm, the iCS2 sensor sets new standards in the miniaturization of modern process sensor technology – without compromising on measuring accuracy. Its innovative design combines powerful technology in the smallest of spaces: at around the size of a golf ball, the sensor can be easily integrated into almost any system and offers maximum precision for a wide range of applications.

| Measuring scales | 100+ standard scales, freely definable custom scales, internal storage one scale |

| Measuring range | 1.3270 – 1.4036 RI / 0 – 40 Brix (up to 50 Brix on request) |

| Resolution | 0.00007 RI / 0.05 Brix |

| Accuracy | ± 0.0002 RI / ± 0.15 Brix * |

| Reproducibility | 0.0001 RI / 0.075 Brix |

| Operating temperature | – 10 to + 60 °C |

| Process pressure | 0-4 bar, up to 10 bar for cleaning process |

| Interface | RS485 Modbus RTU 4-pin M8 plug M8 cable 90° 300 mm |

| Dimension | 44 mm (60 mm incl. 90° Cable) x Ø 40 mm |

| Weight | 155 g |

*Standard conditions (t= 20 °C, p= 1013 mbar)