Laboratory

In-line Process Instruments

Industries & Applications

In-house Services

Product Support

Educational

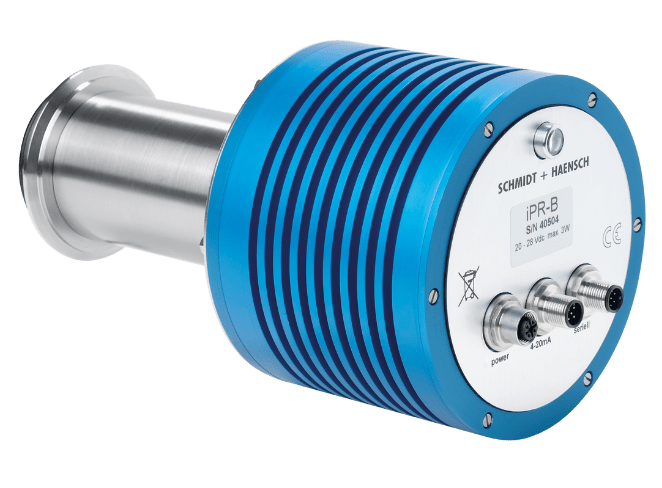

The Basic Inline Process Refractometer (iPR B4) is a powerful refractometer for continuous quality monitoring in the sugar, pharmaceutical and chemical industries. It enables precise determination of the refractive index (RI) in real time – directly in the product stream – thus ensuring stable processes, consistent product quality and higher efficiency. Designed for a wide range of industrial applications, the iPR B series, which has been tried and tested for years, offers excellent value for money and simple, reliable integration into existing systems. As a robust Brix meter, it can be used for real-time quality control and monitoring of sugar concentration in liquids, thereby contributing significantly to increased efficiency and process reliability.

• Attractive entry-level device for the sugar industry – ideal price-performance ratio for precise inline analysis

• Wide measuring and temperature range – perfect for a wide range of applications

• Real-time control directly in the process – maximum efficiency and consistent product quality

• Complete, simple and flexible integration into your process

• Durable, low-maintenance design

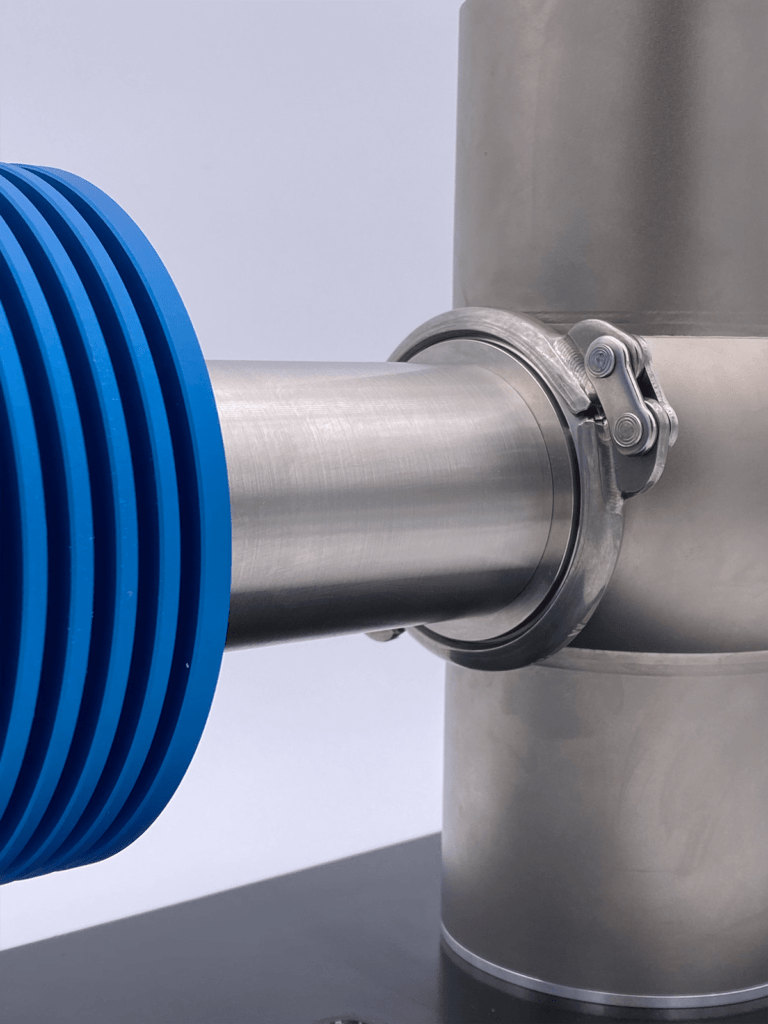

The iPR B⁴ impresses with its straightforward integration into existing process environments. Two isolated 4–20 mA analogue outputs and two digital switching outputs enable flexible connection to your control technology – for example, to control a connected valve or relay. This allows, for example, the cleaning of the measuring prism to be conveniently automated via a solenoid valve. In addition, a serial RS232 interface is available for direct communication and data output. The user-friendly UniConfig software included in the scope of delivery supports you in configuration and data acquisition, ensuring uncomplicated commissioning and full control over your measured values. The iPR B⁴ can be integrated into pipelines, reactors, containers or mixing tanks using various weld-in flanges. Alternatively, a VariVent connection enables quick and tool-free installation via a plug-in clamp connection.

For special, complex applications, cleaning of the sensor surface may be necessary. SCHMIDT + HAENSCH therefore offers an optional cleaning nozzle or a specially developed ultrasonic cleaning device, which can be installed opposite the process refractometer.

The iPR B⁴ is the ideal solution for continuous monitoring of the refractive index, interpreted as a customer-specific value such as the sucrose concentration (Brix value) in liquids – especially in sugar factories and sugar-processing industries as well as the agricultural industry. In the production of cane and beet sugar, molasses, syrup, jam or various confectionery products or beverages such as lemonade and fruit juice, the iPR B⁴ can be used to identify liquids and distinguish between substances for interface purposes. It is also suitable for other applications where precise concentration control is required, such as peptide synthesis or processes in mechanical engineering and automotive manufacturing. Its wide measuring range makes it flexible in use.

Do you have a special requirement? Our experienced team of engineers will tailor the process refractometer precisely to your application – get in touch with us!

The sophisticated design of the refractometer features a blue anodised air cooling jacket. This cooling jacket protects the electronic components from overheating at high process temperatures. Equipped with a light source at 589 nm, the iPR B⁴ delivers highly accurate RI values directly during the process – without any time loss due to manual sampling. A real added value for anyone who wants to balance cost-effectiveness and quality. CIP cleaning at the prescribed temperatures is possible without removing the device when it is switched off.

In addition to the Brix scale, SCHMIDT + HAENSCH offers many other scales such as Oechsle, ethylene glycol, sodium chloride, urea, etc. Can’t find the analyte you need? Just contact us and we will find a solution together!

| Measurement principle | Total internal reflection |

| User scales | Sucrose (Brix) (already included) Up to 4 scales freely definable |

| Measuring range | 1.32000 – 1.51000 RI / 0 – 85 Brix |

| Accuracy | ± 0.00007 RI / ± 0.05 Brix at 25°C |

| Resolution | 0.00001 RI / 0.01 Brix |

| Reproducibility | 0.00005 RI / 0.036 Brix |

| Process temperature | – 10 to + 90 °C |

| Ambient temperature | – 10 to + 50 °C |

| Temperature sensor accuracy | ± 0.1 °C |

| Temperature measurement | NTC sensor for measurement of sample temperature placed inside the prism |

| Process pressure | 0 – 10 bar |

| Interfaces standard | 2 insulated 4 – 20 mA analog outputs 2 digital output switch (up to 1 A) 1 serial output (RS232) |

| Interface optional | 1 serial output (RS485 or USB) |

| Mechanical interfaces standard | VariVent type N 1.4404 Stainless steel |

| Mechanical interface optional | APV 1.4404 Stainless steel |

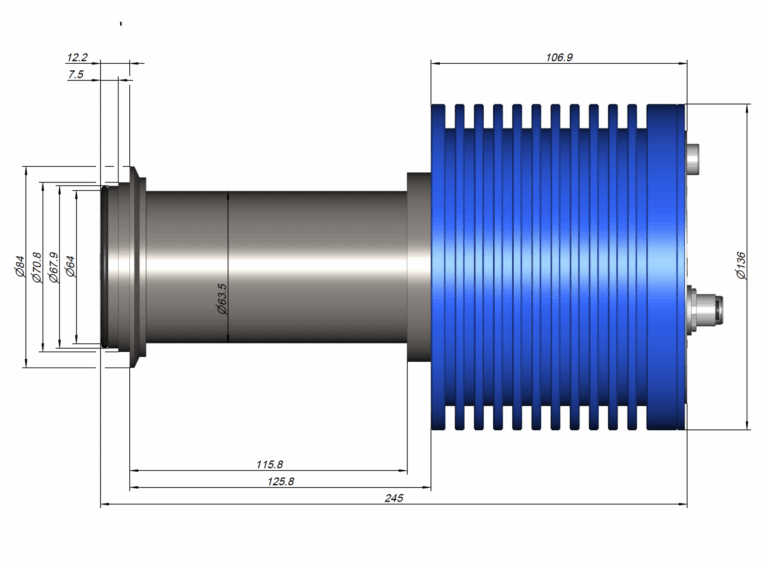

| Dimensions, weight | 245 mm x Ø 136 mm, 5300 g |

| IP class | IP69K |

| Light source, wavelength | LED, 589 nm |

| Power supply | 24 V DC |

| Current consumption | < 120 mA (20 – 28 V) |

| Wetted parts | Sapphire, 1.4404 Stainless steel |

| Housing material | 1.4404 Stainless steel |

| Available immersion depths | 0 – 90 mm |

High-quality laboratory instruments, process analytical systems and automation solutions.

Ensuring your product’s highest quality standard since 1864.